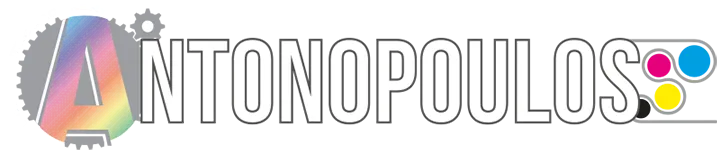

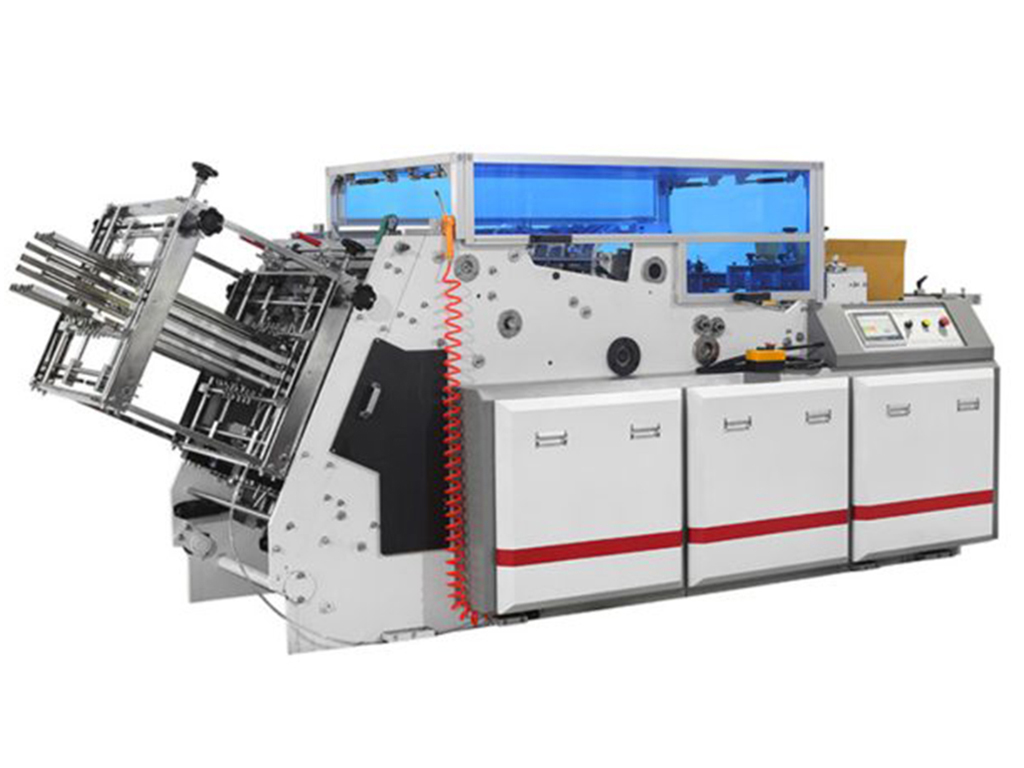

Automatic Paper Carton Erecting Forming Machine

- You can find this machine in different sizes and with different equipment.

Type and Sizes

Machine description

HBJ-D800/1200GS paper carton erecting machine is an ideal choice to produce hamburger boxes,chips boxes,take away box,etc. It adopts micro-computer,PLC,servo feeding,alternating current frequency converter ,the vacuum-sucking,auto gluing,automatic paper tape counting,chain drive.All of these main parts and electric control system adopts famous brand to guarantee steady working,precise positioning,smooth running,safety and reliability operation.

Technical Specifications

| Type | HBJ-D800GS | |

| Production capacity: | 80-200pcs/min | |

| Suitable Material: | 200-600gsm card paper,PE coated paper, kraft paper, corrugated paper(up to 1.5mm) | |

| Paper open length: | L100-450mm degree:5°-40° | |

| Paper open width: | W100-600mm Height H15-200mm (for special sizes can be customized) | |

| Total Power: | 5KW | |

| Weight: | 2.2T | |

| Dimension: | 3600 x1400 x 1700 mm | |

| power source | 380V 50HZ( can be customized)) | |

New Characteristic in structure

1.Full servo motor machine:

1)Servo motor on the paper feeding

2)servo motor on the main motor

3)Servo motor on the box forming part

2.Hidden Electrical box

3.New sloping pathway

4.paper feeeding by rotating wheel with narrow belt

5.IOT technology

6.The pneumatic knife

Description

Additional information

| Availability | Available for Ordering |

|---|---|

| Brand | Dakiou |

| Condition | New |

| Status | Out of Stock |

| Model | HBJ |