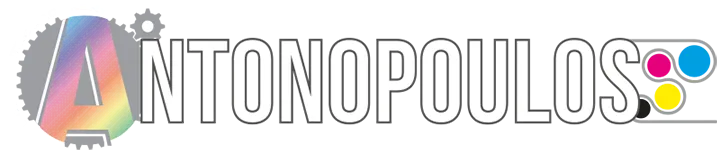

Aoer Fully Automatic Die Cutting Machine

- You can find this machine in different sizes and with different equipment.

※Features

1. The machine made by professional precessing, with scientific structure. Easy to operation, professional safety performance, large cutting pressure to make high benefit.

2. Suitable for paper board, corrugated board, PP, PVC, concave-convex printing etc. Wide field of application, long service life.

※Introduction:

◆ Feeding: Adopt synchronous transport, smooth running, feeding shelves with air spring can make operation more easily. There are push, pull, dual-purpose type side gauge on the both of side, with adjustable front gauge location device, imported laser location device to make location more precision. Also have empty sheet, skew sheet, double sheet control device to ensure the feeding precision smooth, reduce the waste of paper, single point clutch function can make feeding and cutting separation anytime or synchronous combining, it makes operation more easily.

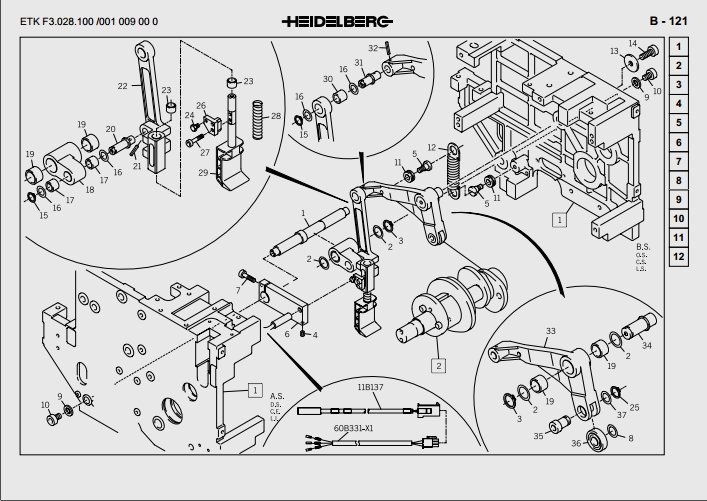

◆ Stripping: The stripping device made with above frame, middle frame, below frame, these 3 linkage frame can transport power easily, camshaft curvilinear motion, it can improve the stability of stripping. With middle line frame can fast change the mould. The preset shelves (optional) can make pre typesetting out of machine to reduce the typesetting time. Stripping air stopped device to extend the service life.

◆ Delivery: Adopt mechanical drive brush press paper device, with dibirectional blowing device to devlier paper smoothly. Set the speed reduction or stop delivery after paper’s full, also can choose unstop delivery with vice delivery device, take sample with air control, make lable for any number of piece paper, setting automatic stop after reach setting pieces function.

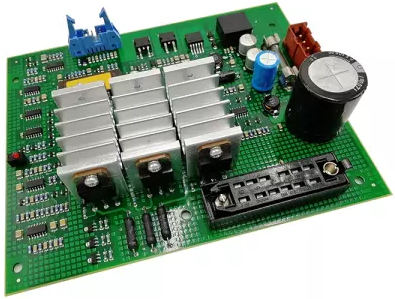

Other: The machines adopts imported electrical parts, imported bearing. Internal and external lubrication, internal parts adopts oil circulation system and external parts use PLC automatic control oil pump system to keep machine running smooth, high speed, increased the machine life. The man-machine interface is easy for make operation, also have fault display function, can notice the fault with sound and light alarm to get troubleshooting on time. The flash memory disk (USB) can upgrade system very easily.

※Main Technical Parameter:

- Max. Paper size: 1080*780MM

- Min. Paper size: 400*330MM

- Max. die-cutting size: 1075*770MM

- Die frame inner size: 1100*790MM

- Stock Range:1). Paper (depending on quality). Min.: 90g/m2

2). Board (depending on quality) up to (*): 1000g/m2 3). Corrugated Board, up to (*): 4mm

(*) Carton acceptable wrap: 2% of the width wise sheet - Min Gripper Margin: 9~17mm

- Cutting rule Height: 23.8mm

- Minimum width of double cuts: 5mm

- Maximum Mechanical speed: 7000cycles/hour

- Max cutting pressure: 260T

- Maximum pile height at Feeder-Normal mode: 1800mm

- Maximum pile height at Feeder- Non-stop: 1520MM

- Dimension (L(+pre-stacking) *W(+platform)*H: 5880(+1650)*2100(+1650)*2350M

Description

Additional information

| Availability | Available for Ordering |

|---|---|

| Brand | Aoer |

| Condition | New |

| Model | 1080 QB |

| Sheet Size | 78×108 cm |

| Status | Out of Stock |